Product Development & Prototype

High Quality Tactical Solutions

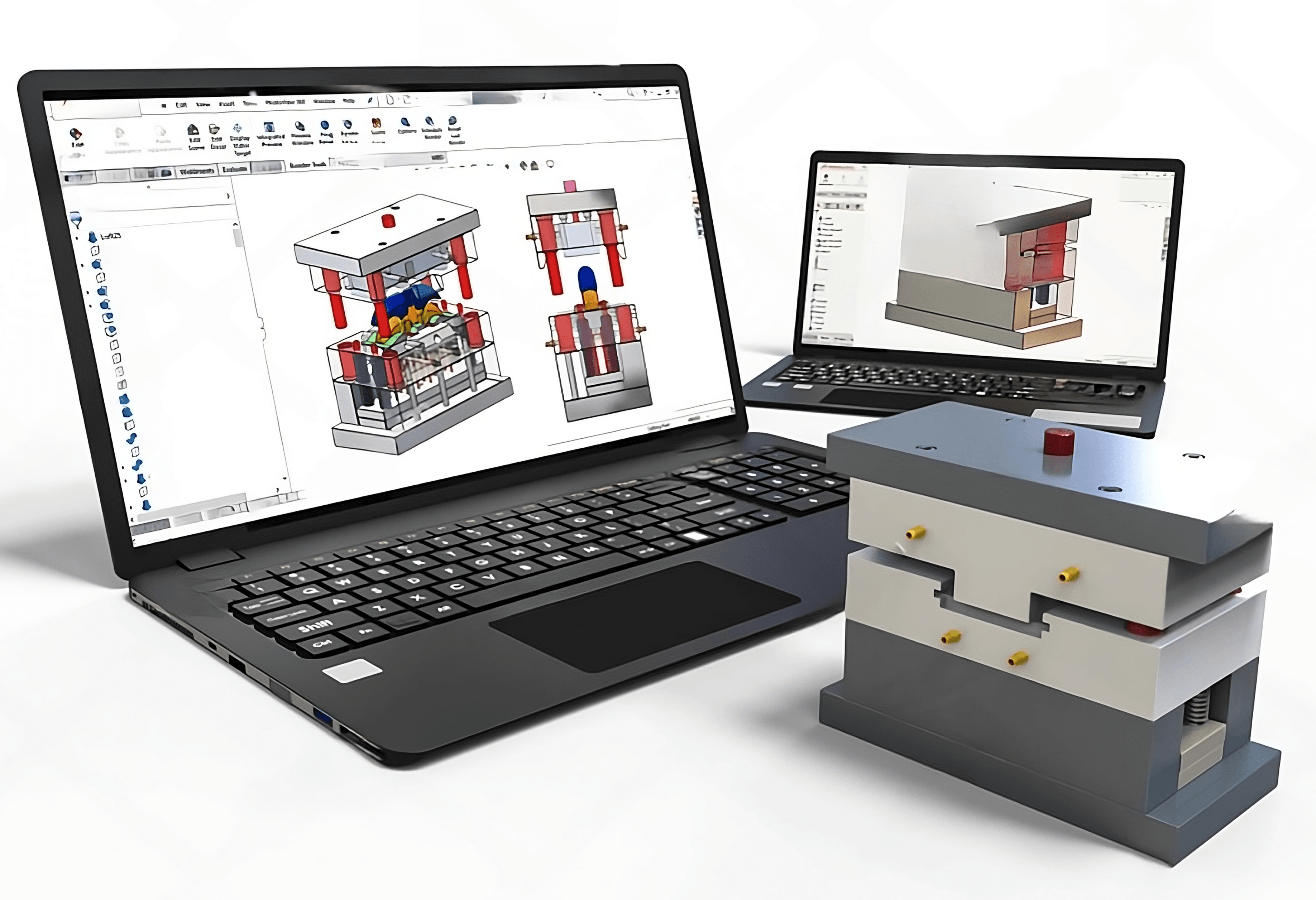

Bringing Your Product to Life, Seamlessly

Our project management approach ensures your product moves smoothly from concept to completion. Whether it’s a prototype, a multi-cavity mould, or full-scale production, we provide a dedicated team and clear communication at every step

How We Manage Your Project

Initial Contract & NDA

We respect your intellectual property. Signing a Non-Disclosure Agreement (NDA) is standard practice, ensuring your ideas are protected. Once agreed, we initiate a no-obligation audit of your project, followed by technical advice and a tailored quote.

Design for Manufacture (DFM) Review

Our engineers conduct an in-depth DFM review to optimize your design for injection moulding. This process ensures cost-effectiveness, precision, and manufacturability while identifying potential improvements.

Project Launch

A dedicated project manager is assigned to your project, serving as your main point of contact. A detailed timing plan with clear milestones is developed and shared, keeping you informed every step of the way.

Tool Design & Manufacturing

– Tool design approval with general assembly sign-off.

– Weekly updates with progress images and timing reviews to ensure timelines are met.

Tool Trials & Validation

We perform comprehensive tool trials to verify reliability and quality. Clients are welcome to participate in this stage, with samples and a full Initial Sample Inspection Report (ISIR) provided for review.

Approval & Production Readiness

Upon successful validation, we provide Production Part Approval Process (PPAP) documentation (Levels 1-3) to meet your requirements. Retained master samples ensure consistent production quality.

Quality Assurance

– Custom quality plans for each component.

– Advanced dimensional analysis and capability studies to maintain precision at full production scale.

Mass Production & Continuous Improvement

Following approval, your project transitions to production, managed through our ERP system for scheduling and quality control. Our team monitors performance metrics and suggests continuous improvements to maximize efficiency and reduce costs.

Why Choose Us?

Are you thinking of making a mould? We are all ears!

Click here to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.