Quality

Why does Quality Matter?

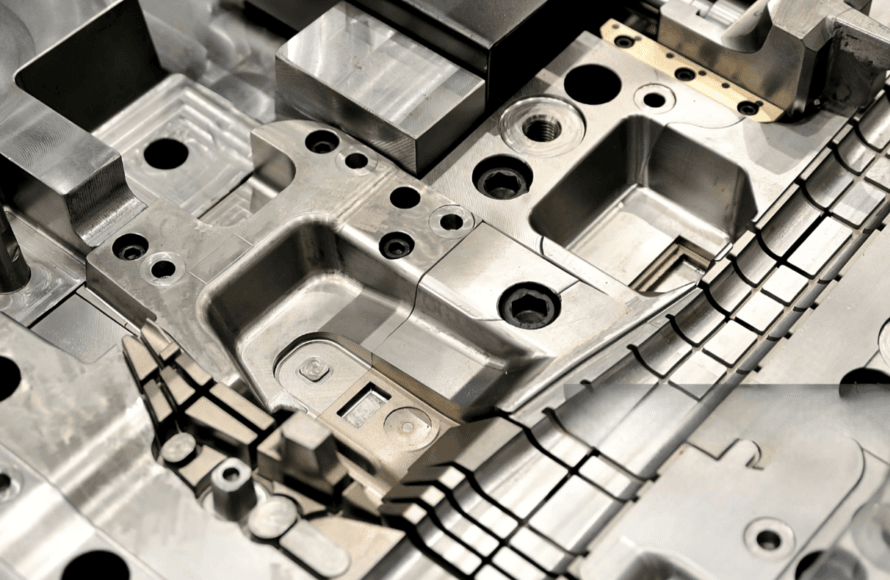

Quality is the cornerstone of successful moulding and mould manufacturing. In industries where precision, reliability, and efficiency are non-negotiable, ensuring the highest quality standards in every stage of the process is essential. At our company, we are committed to delivering excellence in both mould manufacturing and plastic moulding, ensuring our clients receive products that meet and exceed expectations.

Our Approach to Quality

Quality Comes First! We Make Sure That Every Minute Detail Is Looked Into While Manufacturing Even The Smallest Product. Our Focus Is 100% On Client Needs And Satisfaction.

- Material Selection: Choosing the right thermoplastics for strength, durability, and performance.

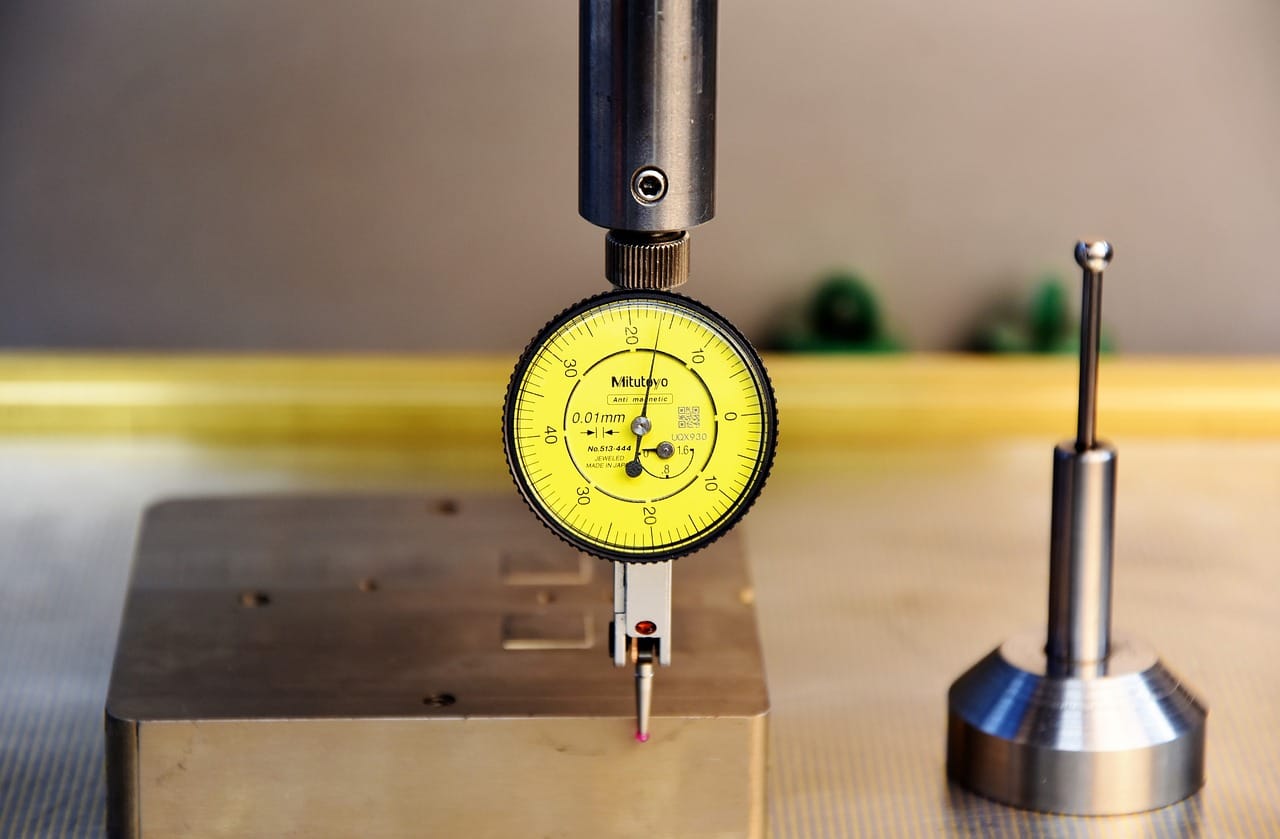

- Process Control: 360° monitoring of temperature, pressure, and cycle times to ensure consistency.

- Post-Production Inspection: Every part undergoes rigorous quality checks, including dimensional accuracy, appearance, and functionality tests.

- ISO 9001: Quality Management Systems.

- PPAP: Production Part Approval Process for consistent quality validation.

- APQP: Advanced Product Quality Planning for seamless production.

Commitment

Continuous Improvement

Our commitment to quality doesn’t stop at delivery. We continually review our processes, incorporate customer feedback, and invest in the latest technologies to stay ahead in the industry. This dedication to improvement ensures that our customers always receive the best in moulds and services.

Quality, Excellence

When it comes to mould manufacturing and injection moulding, quality is not just a priority—it’s our promise. Partner with us to experience the perfect blend of precision, reliability, and innovation.